MISSION

Contributing to the Circular Economy

The circular economy refers to an economic system in which products and raw materials that have been "discarded" in the conventional linear economic system of "Take", "Make" and "Waste" are regarded as new "resources". These resources are circulated without producing waste.

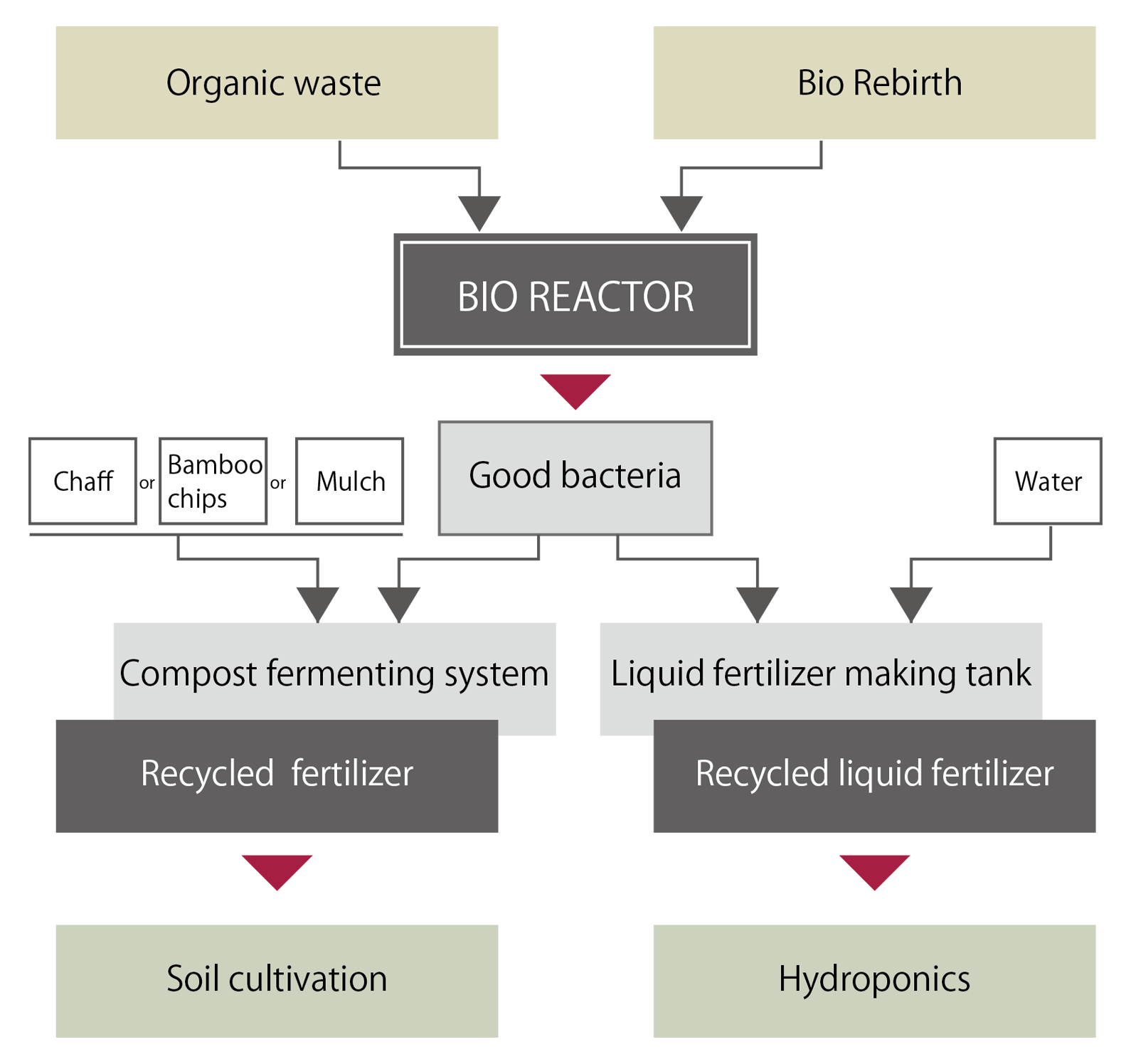

Product Design MASAKUNI contributes to the realization of the circular economy by manufacturing food recycled compost using -bioreactor-, an independently developed organic waste recycling system.